Impact Testing

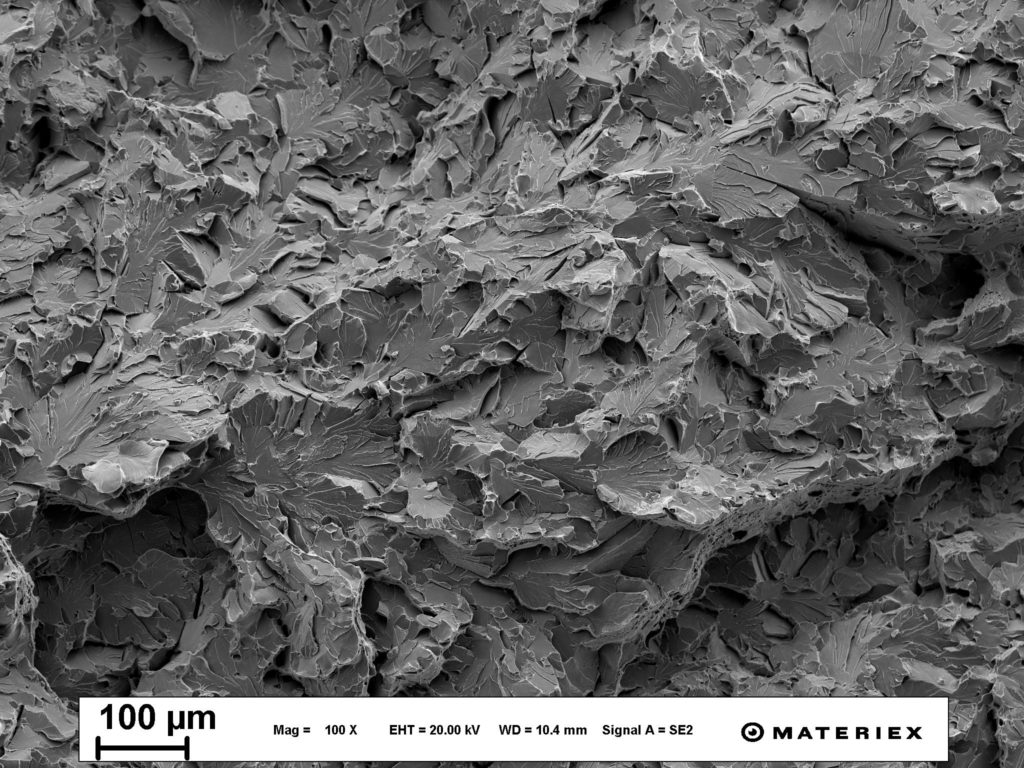

Impact testing is a commonly used method to identify how much energy a material can absorb during collision. The absorbed energy can be used to determine material properties such as toughness and fracture resistance. The technique is also typically used to determine materials behaviour at different temperatures and does often play a significant role when it comes to identifying critical temperature ranges for a certain material, such as ductile-brittle transition. After an impact test has been conducted, the fracture surface of the test specimen may be studied using electron microscopy (SEM) to determine the mode of fracture.

Typical applications:

- Determination of ductile-brittle transition

- Identifying critical operating temperatures for a certain material

- Estimation of material properties such as toughness and fracture resistance